River Parish Sequestration Project

Blue Sky Infrastructure’s River Parish Sequestration (RPS) Project is a large-scale CO2 storage hub located in Southern Louisiana along the Mississippi River industrial and chemical corridor between Baton Rouge and New Orleans. This 100-mile corridor has over 55 industrial facilities that emit more than 60 million metric tons of CO2 annually, or approximately 8% of total industrial CO2 emissions in the US.

Blue Sky Infrastructure has secured underground CO2 injection and storage rights underlying over 30,000 surface acres that can store at least 14 million metric tons of CO2 annually and approximately 400 million metric tons of CO2 in aggregate. These locations were strategically selected to provide for the lowest cost CO2 transportation and sequestration solution in the region with suitable geology, proximity to emissions sources, and no or minimal impacts to communities and sensitive environmental resources. Blue Sky Infrastructure has commenced the permitting and development process for multiple UIC Class VI CO2 injection wells and a CO2 pipeline system and expects to be ready to begin CO2 sequestration in 2026.

Timberlands Sequestration Project

Blue Sky Infrastructure’s Timberlands Sequestration (TS) Project is a carbon capture and storage project for a pulp and paper mill located in Alabama. The TS Project will be designed to capture approximately 2 million metric tons of carbon dioxide (CO2) per year for 30 years from the mill’s flue gas and inject that CO2 underground in deep saline aquifers for permanent storage. The TS Project will consist of a carbon capture plant that will remove CO2 from the mill’s flue gas, a pipeline that will transport dense-phase CO2 from the capture plant to the storage site, a Class VI well for CO2 injection into saline reservoirs 4,000 to 7,000 feet beneath the surface, and monitoring wells to track the injected CO2 and sample underground sources of drinking water during and after operations.

River Parish Sequestration Project

Blue Sky Infrastructure’s River Parish Sequestration (RPS) Project is a large-scale CO2 storage hub located in Southern Louisiana along the Mississippi River industrial and chemical corridor between Baton Rouge and New Orleans. This 100-mile corridor has over 55 industrial facilities that emit more than 60 million metric tons of CO2 annually, or approximately 8% of total industrial CO2 emissions in the US.

Blue Sky Infrastructure has secured underground CO2 injection and storage rights underlying 28,000 surface acres that are capable of storing at least 14 million metric tons of CO2 annually and at least 400 million metric tons of CO2 in aggregate. These locations were strategically selected to provide for the lowest cost CO2 transportation and sequestration solution in the region with suitable geology, proximity to emissions sources, and no or minimal impacts to communities and sensitive environmental resources. Blue Sky Infrastructure has commenced the permitting and development process for multiple UIC Class VI CO2 injection wells and CO2 pipeline system and expects to be ready to begin CO2 sequestration in 2026.

Timberlands Sequestration Project

Blue Sky Infrastructure’s Timberlands Sequestration (“TS”) Project is biomass carbon removal and storage (BiCRS) project for a pulp mill located in Alabama. The TS Project will be designed to capture approximately 2 million metric tons of carbon dioxide (CO2) per year for 30 years from the mill’s flue gas and inject that CO2 underground in deep saline aquifers for permanent storage. The TS Project will consist of a carbon capture plant located near the mill that will remove CO2 from the mill’s flue gas, a short pipeline that will transport supercritical CO2 from the capture plant to the injection well nearby, a Class VI well for CO2 injection into saline reservoirs 4,000 to 7,000 feet beneath the surface, and several wells to monitor the CO2 and underground sources of drinking water after injection. Because substantially all of the mill’s fuel source and all of its feedstock are sustainably harvested timber product, the TS Project will make operations at the mill carbon negative.

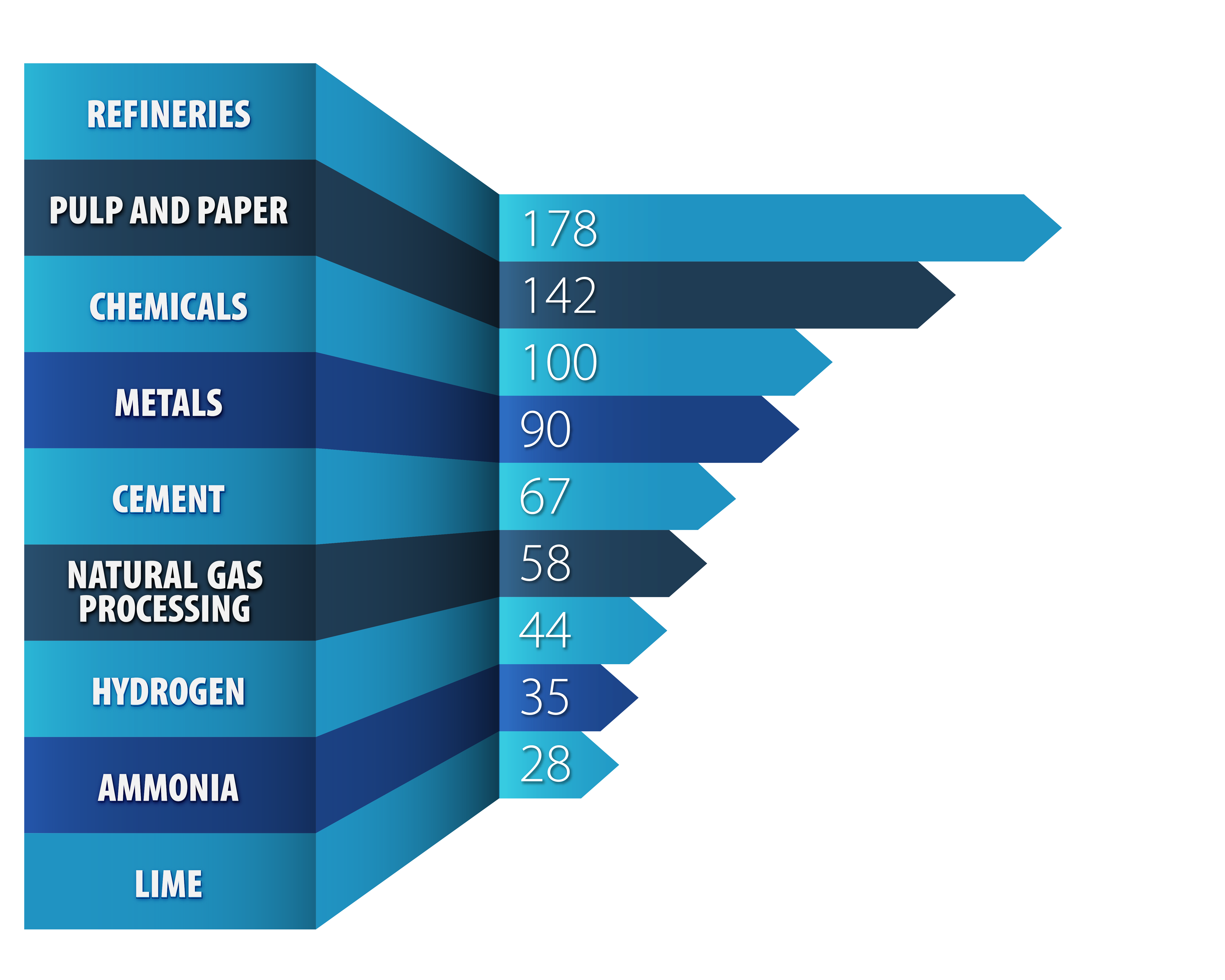

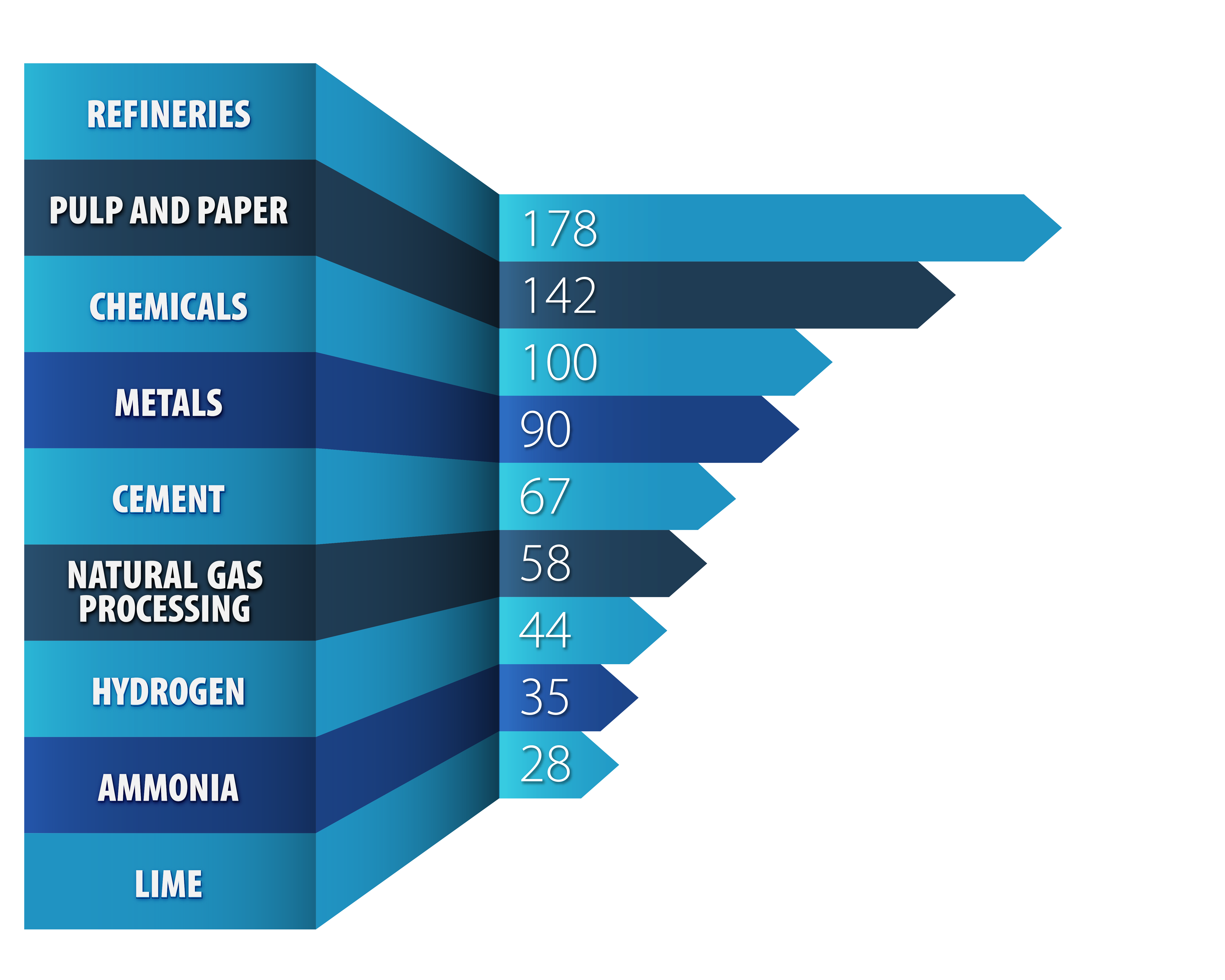

Source for the data is “US EPA (2019)”

Industrial CO2 Emissions

CO2 emissions from heavy industry represent nearly ~15% of total US CO2 emitted or ~740 million tons annually (2019).

Many economically critical industrial applications and processes lack viable alternative production methods that avoid CO2 emissions. High heat intensity requirements make electrification difficult, and many finished heavy industrial products rely on a carbon rich feedstock that results in the release of CO2 during production. Carbon capture and underground sequestration (CCS) is the only currently viable large-scale solution to reduce carbon emissions from US heavy industry.

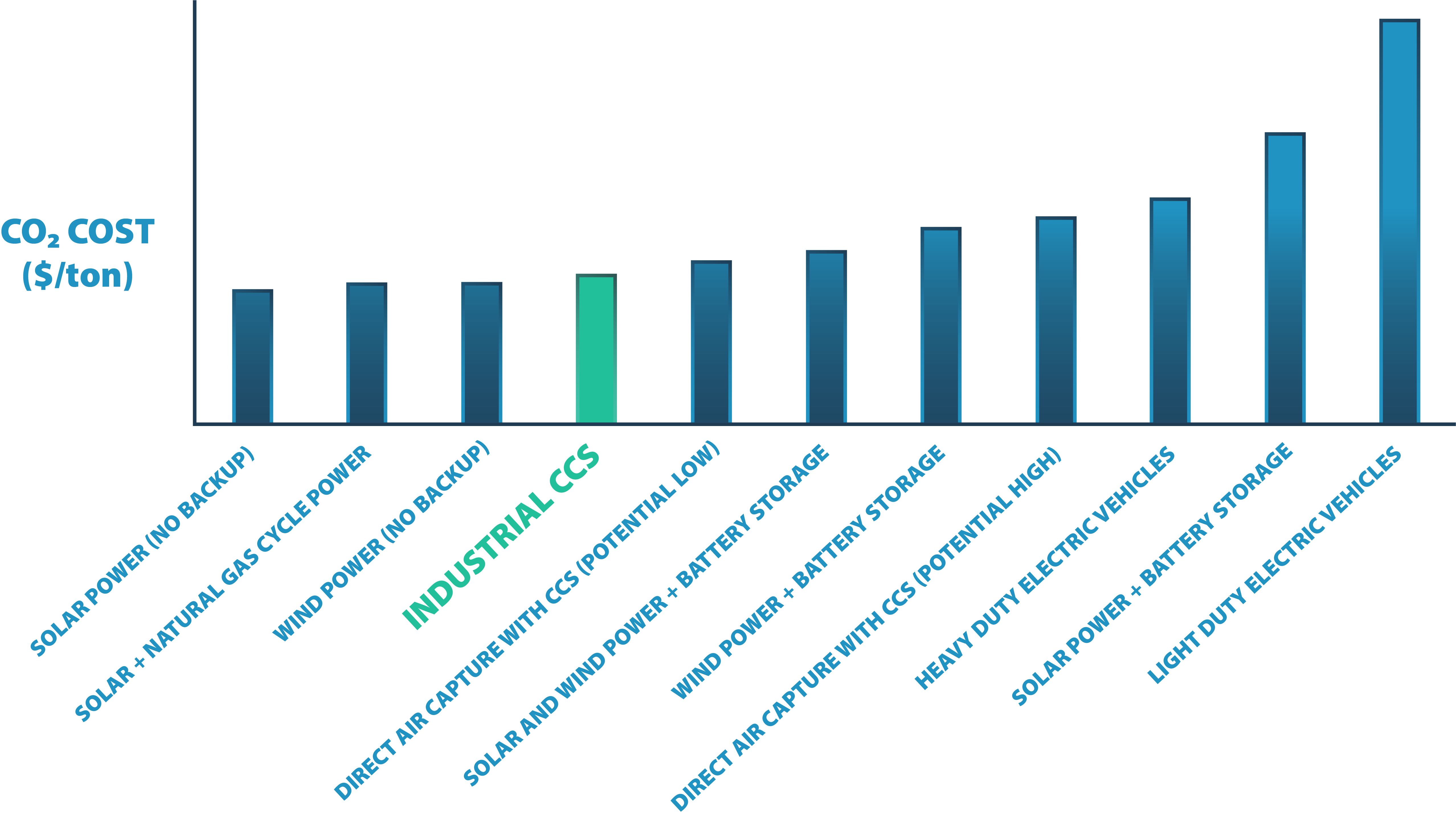

CCS for industrial emissions is a cost-effective and high-impact carbon abatement approach that can be deployed at scale applying existing technologies. The cost of industrial CCS as a decarbonization method compares favorably to other potential large-scale alternatives such as: wind and solar power without fossil fuels using battery storage to mitigate intermittency, electrification of transportation, and direct air capture.

Industrial CO² Emissions

CO2 emissions from heavy industry represent nearly ~15% of total US CO2 emitted or ~740 million tons annually (2019).

Many economically critical industrial applications and processes lack viable alternative production methods that avoid CO2 emissions. High heat intensity requirements make electrification difficult, and many finished heavy industrial products rely on a carbon rich feedstock that results in the release of CO2 during production. Carbon capture and underground sequestration (CCS) is the only currently viable large-scale solution to reduce carbon emissions from US heavy industry.

CCS for industrial emissions is a cost-effective and high-impact carbon abatement approach that can be deployed at scale applying existing technologies. The cost of industrial CCS as a decarbonization method compares favorably to other potential large-scale alternatives such as: wind and solar power without fossil fuels using battery storage to mitigate intermittency, electrification of transportation, and direct air capture.

Avoided CO2 Cost Curve For Certain Material Decarbonization Alternatives

Source is “Blue Sky Infrastructure research and analysis”